Frequently asked questions

Find the answer to your questions below

Can’t find the answer to your question? We are always here to help! Don’t hesitate to contact us.

How does gas liquid porometry work?

Gas Liquid Porometry, also known as Capillary Flow Porometry (CFP), measures pore size and pore size distribution of through pores in materials. The technique is based on the displacement of an inert and nontoxic wetting liquid embedded in a porous network by applying an inert pressurised gas. Therefore, only through pores are measured.

Larger pores become empty first and, as the applied pressure increases, so do the smaller ones until all through pores are empty.

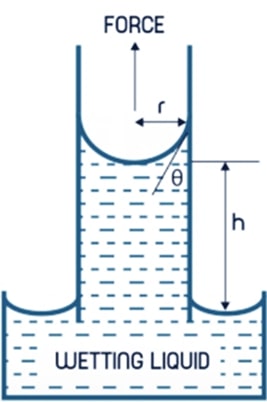

The most challenging part for the gas to displace the liquid along the entire pore path is the most constricted section, also known as pore throat. The diameter measured in CFP is the pore throat, regardless of where it exactly in the pore path is. The method depends upon the capillary rise created by the surface tension between the liquid and the gas. Therefore, a wetted pore immersed in a liquid draws the liquid up the capillary until reaching equilibrium with the force of gravity.

The equilibrium conditions can be expressed

- 2π r γ cos θ = r² π h ρ g …..(1)

- Where r= radius of the capillary (or pore)

- D= diameter of the capillary (or pore)

- h= height of column of liquid

- γ= surface tension of liquid

- ρ= density of liquid

- θ= contact angle between the liquid and capillary wall

- g= acceleration due to gravity and since pressure (P) = hρg, and D = 2r equation (1) becomes

- 2π r γ cos θ = r² π P …..(2)

- P = 4 γ cos θ / D …..(3)

Therefore, the pressure required to empty pores of a certain diameter is inversely proportional to the pore throat size and it is used to calculate the pore size accordingly. The equation 3 is also known as the Young-Laplace formula.”

Our gas liquid porometers are the POROLUXTM Cito series and the POROLUX Revo

How does liquid-liquid porometry work?

Capillary Flow Porometry (CFP) has limitations when it comes to measuring pore sizes in the sub micron and nanometre range. The maximum pressure possible with CFP (35 bars / 500 psi) is not enough to displace the wetting liquid out of the small pores (sizes below 13 nm diameter).

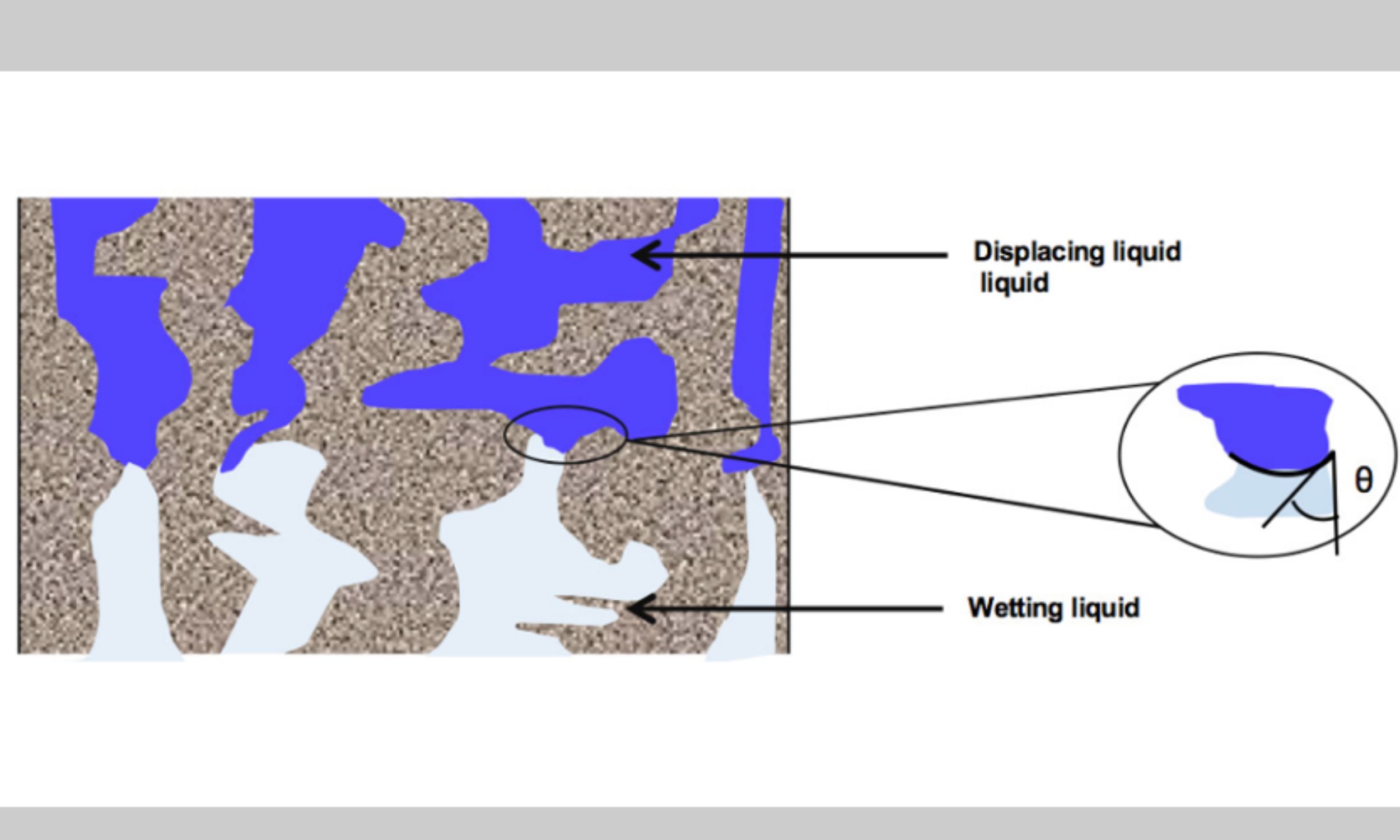

An alternative to CFP for the characterisation of micro and nanopores is liquid liquid displacement porometry (LLDP). The measurement consists of the impregnation of the porous sample with a wetting liquid, but unlike CFP, the displacement of the wetting liquid is carried out by using a second liquid immiscible with the first one (called displacement liquid) at increasing pressure. The Young-Laplace equation is used to calculated the pore sizes.

- P = 4 γ cos θ / D where (P) is the pressure required to displace the wetting liquid from the pore,

- (γ) is the interfacial tension (between the two liquids)

- (θ) is the contact angle

- D= diameter of the capillary (or pore)

The surface tension at the interface between the two liquids is much lower than the surface tension at the interface between a gas and liquid. Hence, the pressure needed to overcome the surface tension is also much lower, and smaller pores can be detected. Since LLDP works with lower pressures, the technique is also very well suited for the full characterisation of hollow fibers as the risk of bursting or collapsing of the fibers is lower.

Our liquid liquid porometers are the POROLIQTM series

What is measured with a Porometer?

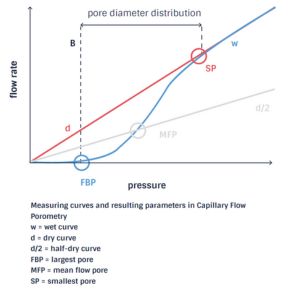

In a typical CFP test, a flow of pressurized gas is applied to the porous sample impregnated with the wetting liquid and the flow of gas through the sample, as the liquid is displaced out of the porous network, is measured. The “wet curve” represents the measured gas flow against the applied pressure. Following the wet curve, the gas flow against the applied pressure on the dry sample (“ dry curve”) is also measured. From data from the wet curve, the dry curve and the “half-dry curve” (dividing the flow values of the dry curve by 2), information about the porous network can be obtained.

A full porometry test can provide information on:

- Bubble point

- Smallest pore size

- Mean flow pore diameter

- Gas permeability

- Cumulative filter flow

- Differential filter flow

- Pore size distribution

- Liquid permeability (optional)

With our enhanced mathematical model, the following additional results can be obtained:

- Total pore number

- Total pore area (% and μm²)

- Open Porosity

- Calculated permeability (darcy)

What is the difference between the 3 ways of determining the bubble point?

BP dPL

BP dPL is the bubble point measured as a deviation from the linearity of a user-defined pressure

This means that the BP is detected by applying a constant flow to the sample chamber. Before the opening of the largest pore, the pressure increases linearly. At the precise moment when the gas flow passes through the sample via the largest pore the pressure increase drops. The user can define the criteria to choose the sensitivity of this bubble point detection.

BP x-ml

BP x-ml is the bubble point measured at a user-defined flow rate

This bubble point is measured by using the pressure required to achieve a certain minimum flow. Since the ASTM F-316-03 norm does not give a unique definition for the minimum flow required through the sample, the user may select a specific, optimal flow for the BP calculations.

BP pCF

BP pCF is the bubble point measured as a user-defined percentage of the cumulative flow

This means that the BP is determined based on the ratio between the wet and dry curves. A user can define the x value of the cumulative flow (0.5%, 1% , 2% etc). As this method is based on the ratio between wet and dry curves, it is independent of the test area. The MFP and SP are determined in a similar way.

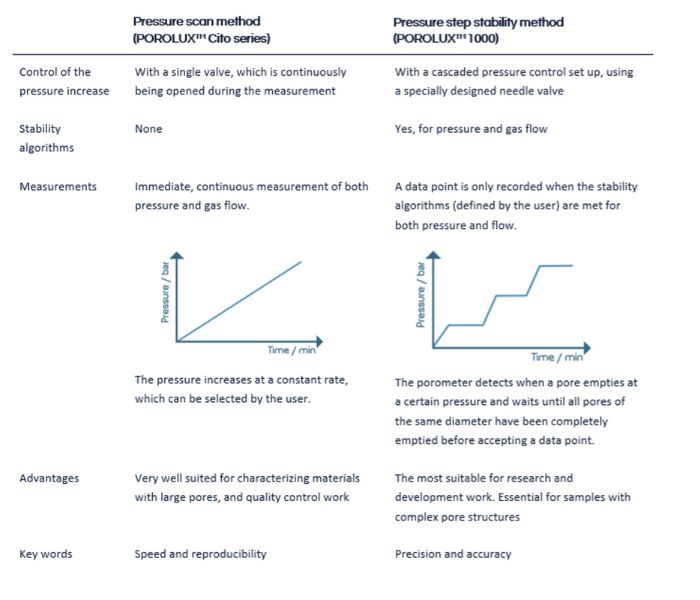

What is the difference between pressure scan and pressure step stability?

Pressure scan:

In this technique, the pressure increases continuously at a constant rate, which can be modified depending on the user's requirements. The resulting flow rates are also recorded simultaneously.

It is a fast and reproducible method that is generally recommended for characterizing materials with larger pores and/or quality control work.

Pressure step stability:

In pressure step/stability technology, the pressure increases stepwise, and the porometer keeps the pressure stable until the flow becomes stable. Meaning, a datapoint will only be accepted if all the pores with the same diameter have opened. This method results in a very accurate pore size measurement and allows to calculate the true pore size distribution

What wetting liquid should I choose?

A good wetting liquid for capillary flow porometry should have the following properties:

- Zero contact angle

- Low surface tension

- Low vapor pressure

Also, it has to be chemically inert and should not cause swelling of the sample.

In many cases, the best results are obtained by using fluorinated hydrocarbons. These liquids have low surface tension (around 16 dyn/cm) and low vapour pressures, which minimises any potential evaporation during the measuement. Sometimes silicone oils are used. They have a high viscosity, a low surface tension and a low vapor pressure. The disadvantage of silicone oils is that it is hard to clean them out of inserts. the sample holder and supports. The residual silicone oil can contaminate subsequent tests, which can prevent the porometer from getting good dry curves.

The use of water is not recommended because it tends to evaporate during measurements, which may lead of an overestimation of the pore sizes (the pores are detected as open too early). Moreover, the surface tension of water is rather high (72 dyn/cm), which means that for a given pore size a much higher pressure than when measuring with Porefil or Galpore is required. Furthermore, water, like some alcohols, often cause swelling of samples.

We recommend using as much as possible the same liquid, because, in theory, as long as you apply the correct vapor pressure, different liquids should give the same results, but in practice it is not always the case.

Porometer offers different types of wetting fluids in different quantities. All of our wetting fluids come with a certificate showing the measured surface tension.