Insights in the new Porometer patented MP² technology

With our most recent product introduction - the POROLUX™ Revo, we have set the bar in pressure step stability porometry by introducing our patented MP² (Multistage Pressure Process) technology. This innovative technology ensures a smooth pressure increase during the measurement and speeds up the process of reaching flow and pressure stability.

Most accurate and reproducible pore size results

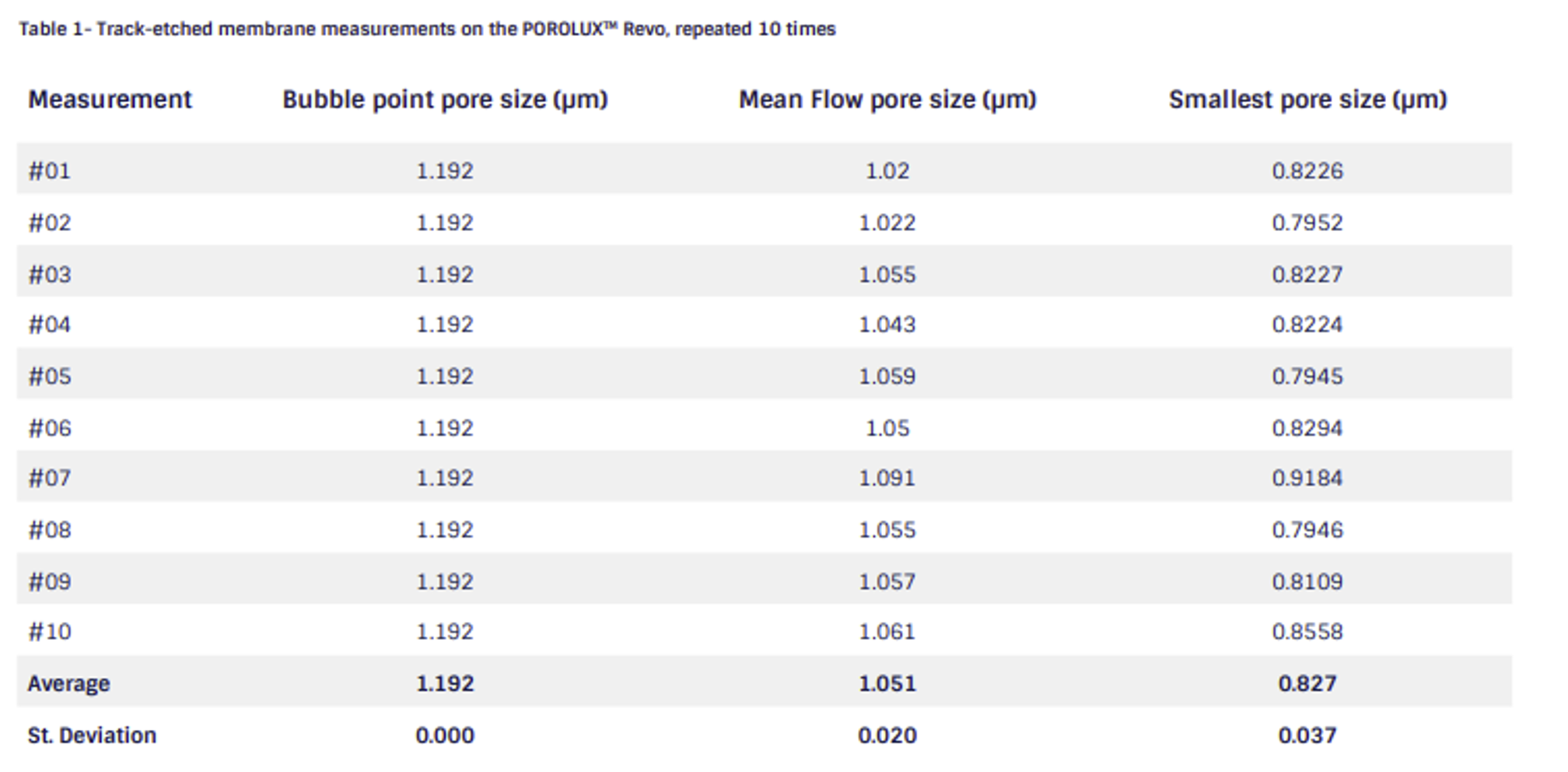

Thanks to the MP² technology, it is now possible to do measurements with smaller, perfectly uniform pressure steps, leading to the most accurate and reproducible pore size results. We have measured a track-etched membrane of 1 μm 10 times and came to a zero standard deviation of the bubble point pore size, as can be seen in the table below.

Testing of a wide range of filtration and separation media

With the MP² technology, a wide range of filtration and separation media can be accurately tested. The graph below shows, amongst others, polymeric membranes, porous metals, and nonwoven fabrics, tested on the POROLUX™ Revo.

More benefits of the MP² technology

The advantages of our patent pending MP² technology summed up:

Most accurate and reproducible pore size results

High resolution

A smoother wet curve and more detailed pore size distribution curve

Challenging samples analyzed in minutes

Wide range of applications

Curious to read how the innovative MP² technology enables us to achieve these benefits? Download our new technical note here.