Energy

Powering the future with pore size measurements

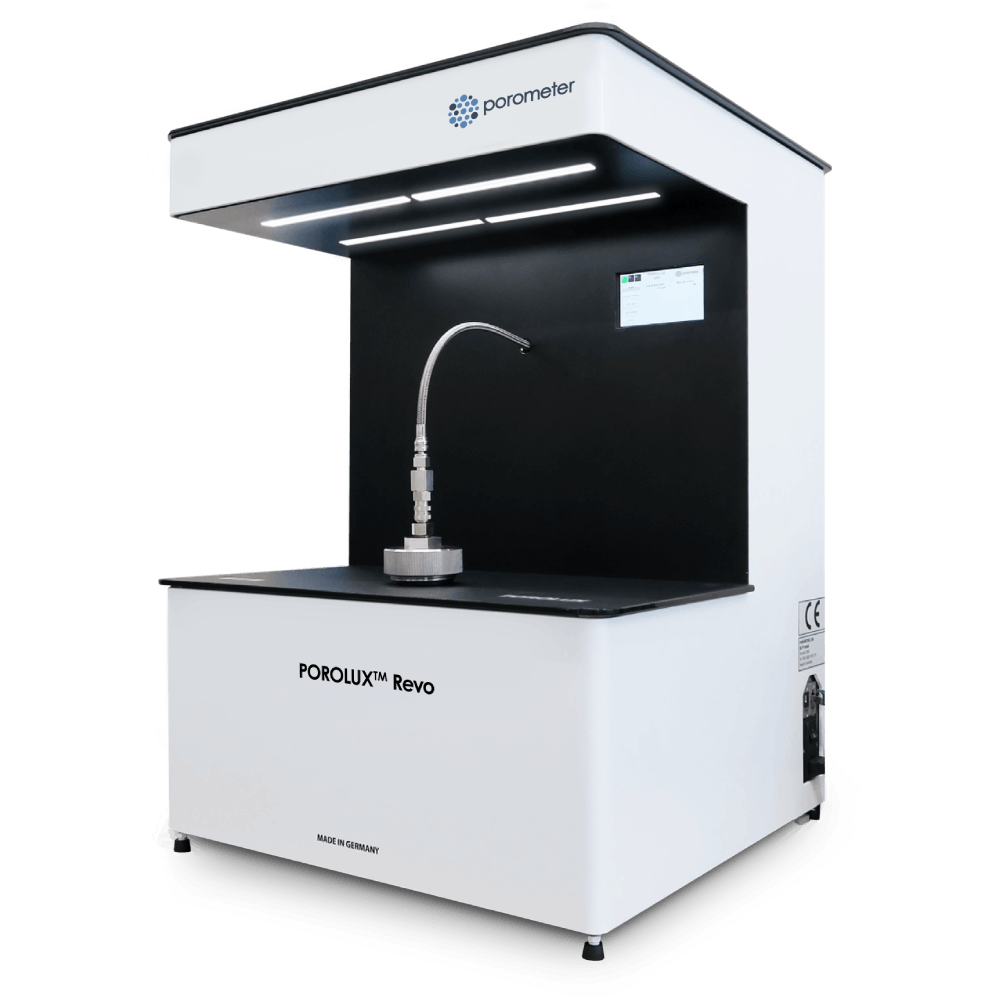

The transition to sustainable energy depends heavily on advanced membranes and filter media. Capillary flow porometry (CFP) plays an important role in the energy sector because many energy-related processes require materials with precisely controlled pore characteristics. Porometers offer valuable insights into pore size, pore size distribution, and permeability, enabling researchers and manufacturers to design, control, and validate these critical parameters effectively.

Fuel cells

Fuel cells are central to clean power generation and play a key role in the emerging hydrogen economy. In certain fuel cell types, porous membranes serve as separators or ceramic matrices.

CFP verifies pore size and distribution in these components, ensuring defect-free structures and long-term reliability. By applying porometry, researchers and manufacturers can optimize fuel cell efficiency, durability, and safety.

Electrolysis

In alkaline and PEM electrolysis, membranes transport ions while keeping gases separate. Porometry helps reduce gas crossover while maintaining conductivity—essential for cost-effective, scalable hydrogen production.

Battery separators

In lithium-ion and solid-state batteries, separator membranes must allow ionic transport while preventing short circuits. Porometry confirms consistent pore size distribution, detects defects, and tracks changes over time—supporting safety, performance, and lifespan.

In the energy sector, capillary flow porometry serves not only as a quality check but also as a development and optimization tool. It aids innovators in enhancing efficiency and reliability in the pursuit of a cleaner energy future

Discover the Porometer difference

Ready to find the right Porometer for your research or quality control application?