Food & beverage

Empowering filtration performance in food & beverage

Filtration is a cornerstone of quality, safety, and efficiency in the food and beverage industry. From dairy and brewing to juice production and ingredient recovery, high-performance filter media are essential to removing contaminants, clarifying liquids, and preserving valuable components.

As consumer expectations and regulatory standards continue to rise, manufacturers must rely on precise, reliable filtration technologies to ensure consistency and compliance across every batch.

At the heart of these solutions are advanced filter media whose pore structure significantly influences process outcomes. Whether optimizing throughput, enhancing product purity, or reducing waste, understanding pore size and distribution is key to selecting the right solution for each application.

Why pore size knowledge matters

Pore size and its distribution determine the size of particles or molecules that can pass through a filter, affecting its retention efficiency and filtration performance. In food and beverage processes, this affects:

Product clarity (e.g. haze removal in beer and wine)

Nutrient retention (e.g. protein separation in dairy)

Microbial safety (e.g. filtration of fermentation by products)

Process efficiency (e.g. minimizing fouling and maximizing flow rates)

“We needed a consistent and reliable way to measure pore size distribution ourselves.”

Too large a pore size risks compromising safety and quality; too small can hinder throughput and increase costs. Accurate pore size characterization helps manufacturers:

Validate the filter’s integrity

Benchmark supplier performance

Accelerate R&D and product development

Ensure compliance with food safety standards

Porometry offers a fast method to analyze pore size distribution, helping manufacturers optimize filter media selection and performance across diverse applications.

How Arla Foods Ingredients ensures reliable membrane performance

See how Arla Foods Ingredients uses pore size measurements to compare membranes and improve filtration performance.

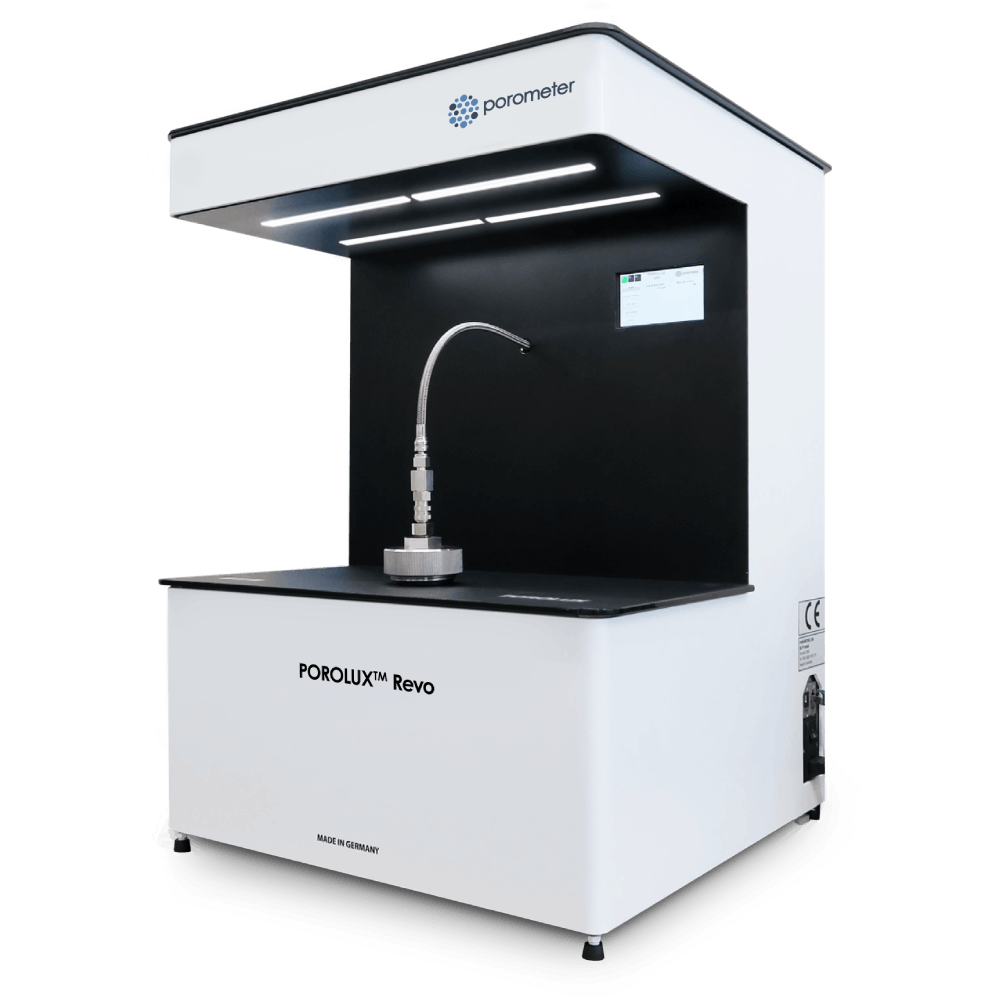

Explore how our instruments can meet your porometry needs

Discover the Porometer difference

Ready to find the right Porometer for your research or quality control application?