Arla Foods Ingredients – Ensuring reliable membrane performance with POROLUX™ Revo

Arla Foods Ingredients Innovation Centre

Arla Foods Ingredients (AFI) is a global leader in whey-based nutrition, developing and supplying high-quality ingredients for early life nutrition, medical nutrition, sports nutrition, and functional foods.

As a 100% owned subsidiary of Arla Foods, AFI combines decades of dairy science expertise with advanced membrane filtration innovation. Their ingredients are clinically documented, supported by strong R&D, and backed by a commitment to sustainability—serving customers across Europe, Asia, and the Americas.

With over 2,000 employees worldwide, AFI’s mission is clear: to deliver documented ingredients that support lifelong nutrition.

The challenge: comparing membranes across suppliers

In their production and research processes, AFI works with membranes sourced from multiple suppliers. Each membrane differs in material, manufacturing process, and pore structure—factors that directly affect separation performance.

While suppliers typically provide datasheets with average pore size or cut-off values, the methods used are not standardized or always disclosed, making it difficult to compare data across suppliers.

“We needed a consistent and reliable way to measure pore size distribution ourselves. While suppliers typically provide datasheets indicating mean pore size or cut-off values, the measurement methods are often not standardized or even disclosed. This lack of consistency makes it challenging to compare membranes across suppliers and select the most suitable one for our specific applications.”

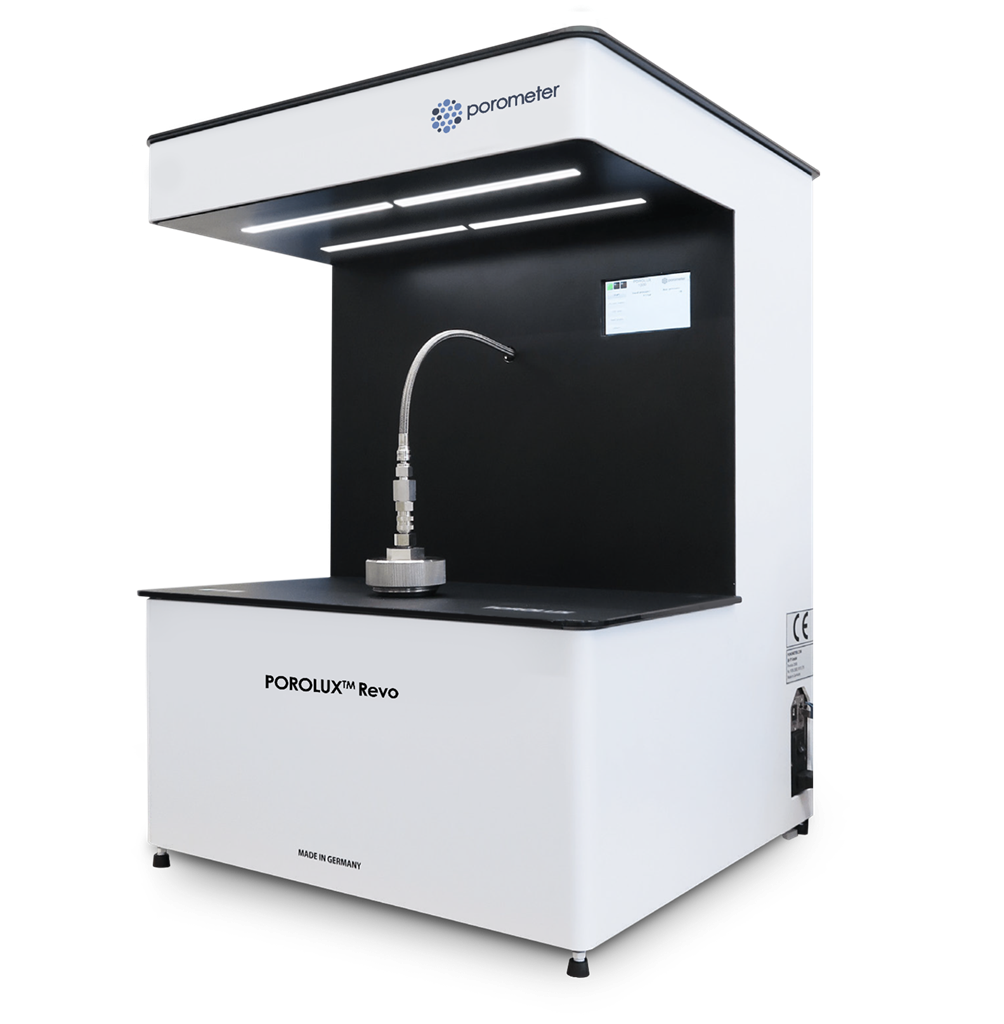

The solution: reliable membranes measurements with POROLUX™ Revo

To address inconsistencies in supplier data and improve internal quality control, AFI implemented the POROLUX™ Revo.

The instrument enabled them to:

Independently measure pore size distribution across membranes

Better understand membrane surface characteristics and their impact on filtration performance

Build a reliable internal databank classifying all membranes in use

Gain insights into the separation processes

Screen alternative membranes for critical applications like milk component separation

Strengthen business continuity by validating backup options

“Our goal is to build an internal databank classifying all membranes in use. Over recent years, we’ve expanded our laboratory capabilities with analytical tools that help us understand membrane surface characteristics and their impact on filtration performance. Adding porometry as a measurement parameter has further enhanced our ability to gain insights into our separation processes.”

Beyond risk management, combining pore size distribution data with other analytical results opens the door for future product development and process optimization.

Does the Porolux™ Revo fit your needs?

Download the product sheet for full specifications.

A strong collaboration with Porometer

The cooperation between AFI and Porometer has been smooth and productive from the very beginning.

“Porometer’s team was highly responsive and supportive—especially during our evaluation phase. They even pre-tested selected samples before we made our purchase decision, which was invaluable in choosing the right model.”

Installation and training went seamlessly, and Porometer’s specialists provided hands-on guidance on measurement techniques, data interpretation, and sample preparation.