Enhancing Membrane Research Efficiency at IIT Roorkee with POROLUX™ Revo

The Indian Institute of Technology Roorkee (IIT Roorkee) stands as one of India‘s premier institutions, renowned for excellence in technological education, engineering, and ground-breaking research. With a legacy tracing back to 1847, when it was established as Roorkee College—the first engineering college in India—this prestigious institute has been at the forefront of shaping the nation’s technical expertise.

IIT Roorkee is recognized internationally for its academic and research excellence and is often ranked within the top 500 of technological institutions globally, making significant contributions across diverse sectors of technological advancement and innovation.

Advanced Membrane Research Lab

Dr. Bhaskar Jyoti Deka, Assistant Professor at the Department of Hydrology and Joint faculty at the Centre for Nanotechnology, IIT Roorkee

The Advanced Membrane Research Lab at IIT Roorkee, led by Dr. Bhaskar Jyoti Deka, focuses on cutting-edge research in membrane technologies such as membrane distillation (MD), forward osmosis (FO), reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF) and microfiltration (MF). Their work addresses global challenges in water and environmental management, particularly in desalination, brine management with zero liquid discharge (ZLD) systems and resource recovery from waste streams.

The team specializes in designing advanced polymeric, nanocomposite and ceramic membranes tailored for high performance in challenging environments. Their innovative approaches to combat membrane wetting and biofouling help enhance membrane durability and efficiency, increasing their suitability for very diverse applications.

Beyond desalination, their research spans water and wastewater treatment, air purification, and membrane development for contaminant remediation and gas separation. A notable focus, however, remains the development of ion exchange membranes for green hydrogen production—contributing to sustainable energy and environmental solutions. With a multidisciplinary approach, they are advancing the future of membrane technology and environmental sustainability.

“The boost in efficiency brought us closer to our research goals and allowed us to file patents earlier, positioning our work for quicker commercialization and industry application.”

Challenges encountered prior to adopting POROLUX™ Revo

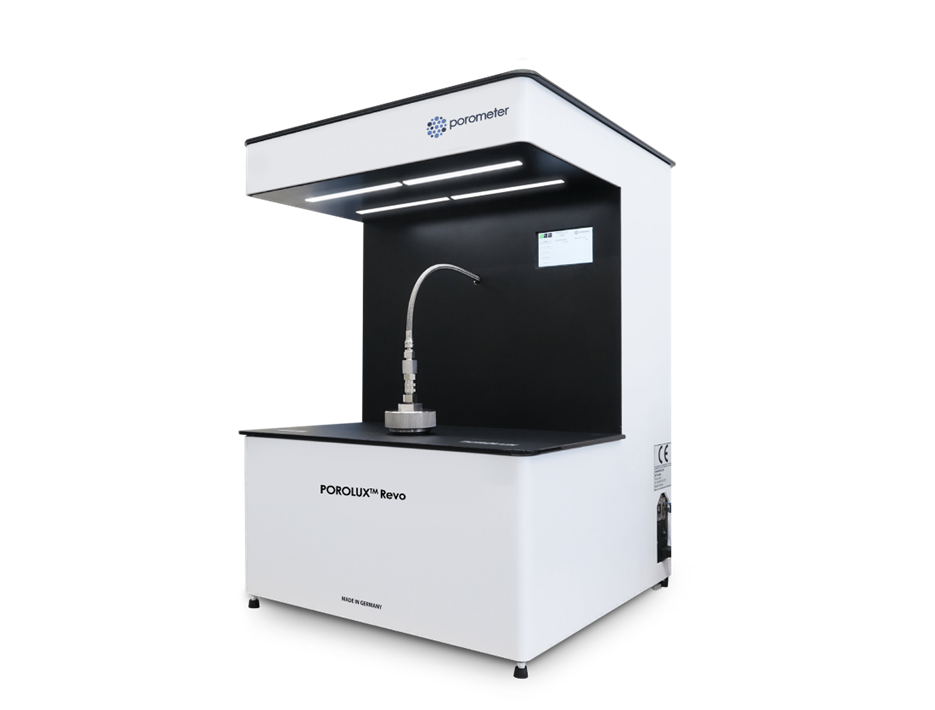

POROLUX™ Revo pressure step stability capillary flow porometer.

Before integrating the POROLUX™ Revo instrument into IIT Roorkee’s research facilities, the scientists faced considerable challenges in accurately measuring essential parameters of their membranes such as pore size distribution, bubble point (the maximum pore sizes), the mean flow pore size, and the smallest pore size. While they could fabricate membranes for various applications, they often relied on other methods, such as scanning electron microscopy (SEM) to assess pore morphology, and Brunauer-Emmett-Teller (BET) analysis for surface area measurements.

Unfortunately, these approaches did not provide the precise data on pore size(s) and pore size distribution they needed, hindering their ability to optimize the membranes for their intended applications. The lack of accurate measurements led to increased material consumption, higher costs, and greater waste during optimization.

Additionally, these limitations resulted in delays in publications and patent opportunities. They constrained their collaborations with industrial partners, as precise and timely data were vital for advancing research and development.

POROLUX™ Revo in the lab

Sample preparation for testing of a membrane with the POROLUX™ Revo

Incorporating the POROLUX™ Revo into IIT Roorkee’s membrane characterization process has significantly enhanced the understanding of pore characteristics. This instrument has enabled them to measure critical parameters, such as pore size distribution and various pore size parameters, with remarkable precision—eliminating the need for alternative methods. As a result of these precise measurements, the researchers of IIT Roorkee can now tailor their membranes for specific applications, including desalination and gas separation, while reducing material usage and costs. Additionally, the porometer’s speed and reliability has significantly accelerated their research and development by providing detailed data in minutes and streamlining design and fabrication process.

Testing of a membrane with the POROLUX™ Revo

When asked how the porometer instrument helped the team create a better-quality product, Dr. Bhaskar Jyoti Deka, Assistant Professor, Advanced Membrane Research Lab, Department of Hydrology, explains:

“The POROLUX™ Revo has greatly improved our ability to create a higher-quality product by allowing for precise control over pore size, which significantly enhanced selectivity and reduced membrane fouling. This precise control also allowed us to optimize performance and efficiency, making the membranes more durable and effective for specific use cases. Additionally, the porometer played a critical role in accelerating our research by shortening development cycles. With faster and more accurate feedback, we could iterate quickly, refining designs and formulations faster.

This boost in efficiency brought us closer to our research goals and allowed us to file patents earlier, positioning our work for quicker commercialization and industry application. Overall, the porometer helped streamline our innovation process, giving us a competitive edge in developing advanced membrane technologies.”